Every year, 3.5 million pairs of brand-new ski boots are produced using raw materials. But ski boots have a relatively short lifespan – 3 years for rental and 5 years for privately owned – and after that, all boots are sent to landfill. Around 600,000 skiers replace their boots each year. And for outdoor shoes, less than 5% of 24 billion pairs produced each year are recycled or reused. LIFE RESKIBOOT, RecycleYourBoots, and LIFE RE-Shoes are tackling footwear waste, saving raw materials, and tonnes of carbon emissions.

LIFE RESKIBOOT provides high quality and competitive ski boots, made from about 90% of recycled materials for the internal and external parts. These materials come from a separation process using an electromagnet, which is 95% effective in dividing the polyurethane and foamed components. 1 000 pairs of boots will be manufactured, and then tested by skiers on the slopes for safety, quality, and comfort. By 2027, 27 000 pairs of boots will be available for purchase; each pair having saved waste, carbon emissions, and raw materials. RESKIBOOT will save 61 500 kg of waste from being sent to landfill, 200 tonnes of greenhouse gas emissions, and 7 500 gigajoules of oil and natural gas required to produce raw materials.

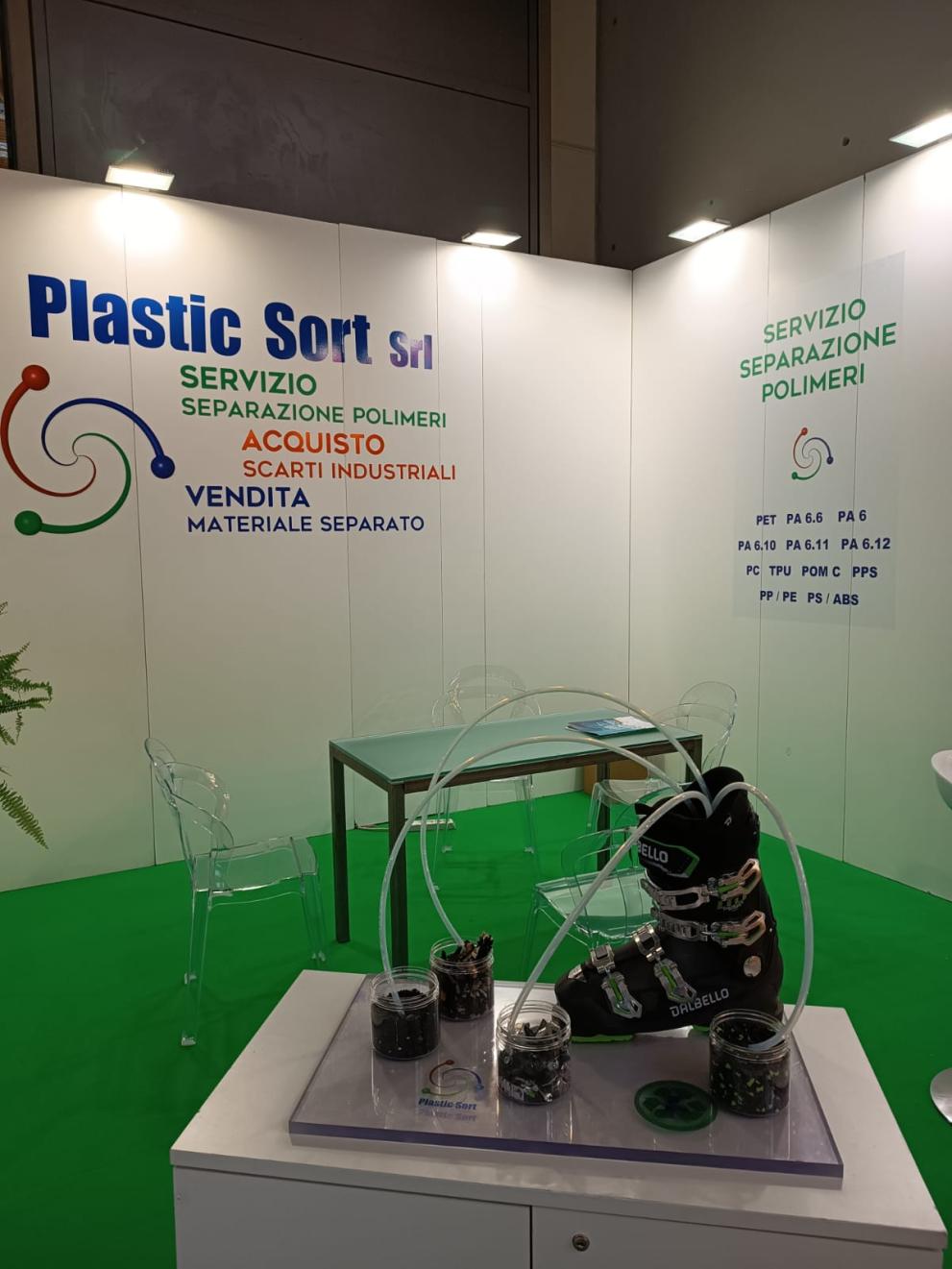

RecycleYourBoots takes ski boots destined for landfill, from 1 500 shops in Austria, France, Germany and Italy via a digital platform, for dismantling and recycling. In Italy, a plant disassembles, washes, shreds, and dedusts the plastic materials, before they are separated and treated. This focuses particularly on the inner shoe components, made out of foams and fabrics. By the end of this year, almost 110 tonnes of waste plastic will have been recycled, and over 600 tonnes of carbon emissions saved. All in all, around 30 000 ski boots will be reclaimed using this process, with the separated materials ready for their industry reuse.

And if hiking is the preferred mountain activity, LIFE RE-Shoes is giving old outdoor boots a new life through an alternative, circular and sustainable solution. Many outdoor shoes cannot be recycled because they are often made from a mix of leather, foam, rubber, plastics, textiles, metals and poly-laminates glued together, and very difficult to separate. But instead of leaving such shoes in landfill, or the back of a wardrobe, LIFE RE-Shoes is collecting, sorting and recycling outdoor shoes past their use. The recycled materials are then used in the manufacturing of new high-quality recycled shoes, ready to traverse the mountain paths again for many more years.

All 3 LIFE projects align with a number of EU legal acts: Waste Framework Directive, European Strategy for Plastics in a Circular Economy; Circular Economy Action Plan 2020; Landfill Directive; Roadmap to a Resource Efficient Europe; Towards a circular economy: A zero waste programme for Europe; and Closing the loop - An EU action plan for the Circular Economy.

Details

- Publication date

- 4 January 2024

- Author

- European Climate, Infrastructure and Environment Executive Agency