FUJIFILM

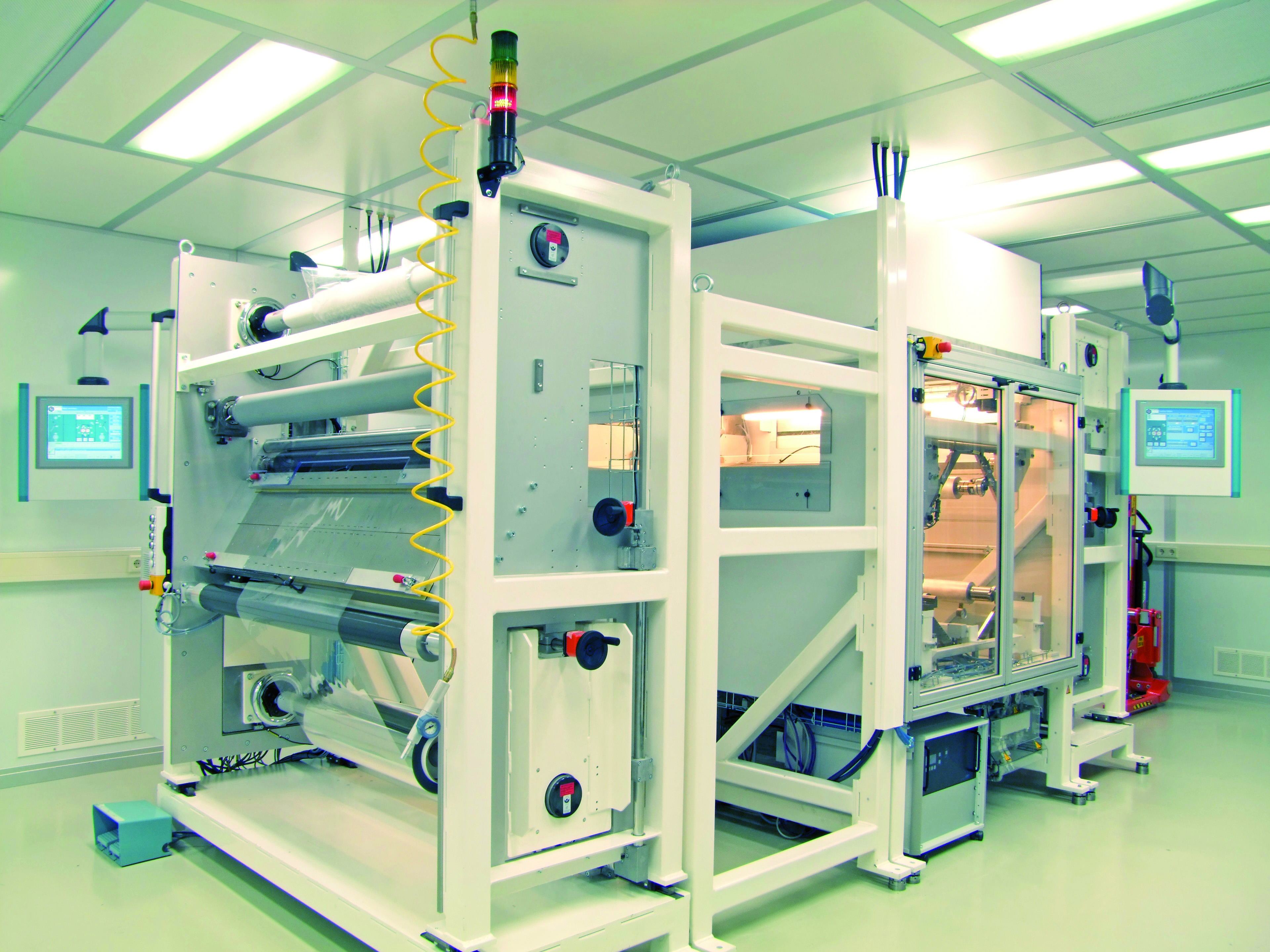

As a world leader in thin film coatings, Fujiflm is pioneering a more efficient and environmentallyfriendly way of manufacturing flexible solar cells. Our new plasma-based technique saves energy and natural resources by depositing microscopically thin layers of material with a cloud of gas that we can now energise under standard pressure conditions.

Larger with Life

In 2013-2016, the EU LIFE Programme invested €1.9 million in the €4.5 million Green Plasma project to help tailor a new manufacturing technique to the needs of its first customers. Fujifilm’s so-called Atmospheric Pressure Glow plasma for Chemical Vapour Deposition (APG-CVD) has since broadened the options for manufacturing rolls of flexible solar cells. The new plasma-based technique consumes less energy and raw materials to produce the same quality of solar cells.

EU added value

- Plasma-deposition 20% cheaper

- Greener solar cell manufacturing

- Shift to non-toxic raw materials

Prospects

- Estimated €500 million PV market

- Revitalise EU renewables industry

- Tech protected by 20+ patents

Achievements

- Reduced raw materials wasted by plasma-deposition techniques from 80% to 10%

- Brought down energy consumption of plasmadeposition techniques by 95%

- Demonstrated the potential for production at web speeds of 50 meters a minute

- Built a first on-site APG-CVD system for customer demonstrations in 2015

Policy support

- Accelerate the introduction of renewable energy in line with the energy union strategy

- Efficient use of natural resources as set out in the 7th environment action programme

- Strengthen industry and competitiveness in agreement with the EU industrial policy strategy

- Project locations

- Netherlands

- Project website

- www.green-plasma.eu