The objective of ATOMS project is to lower operation & maintenance costs for offshore wind farms. The project launched and tested a new technology for large corrective maintenance operations of wind turbines, which does not rely on the use of large marine cranes and heavy-lift jack vessels. This significantly reduces both costs and environmental impact.

Operational Expenses (OPEX) cover nearly 30% of the costs of the offshore wind energy. About half of the OPEX cost is used to pay for big jack-up vessels that until now have the monopoly of the so-called large corrective maintenance actions, such as the replacement and handling of major wind turbines’ components.

These maintenance actions are therefore a crucial issue in the cost of this energy. While recent efforts have focused on reducing the cost of electricity production through larger turbines, operation & maintenance actions – a critical cost factor – have been overlooked. The ATOMS project aimed to lower overall offshore wind energy costs while minimizing environmental impact.

How ATOMS system reduces cost and environmental impact

ATOMS innovative system consists of three main elements:

- a mid-size floating twin hull barge,

- a conventional onshore crane and

- a coupling ring structure.

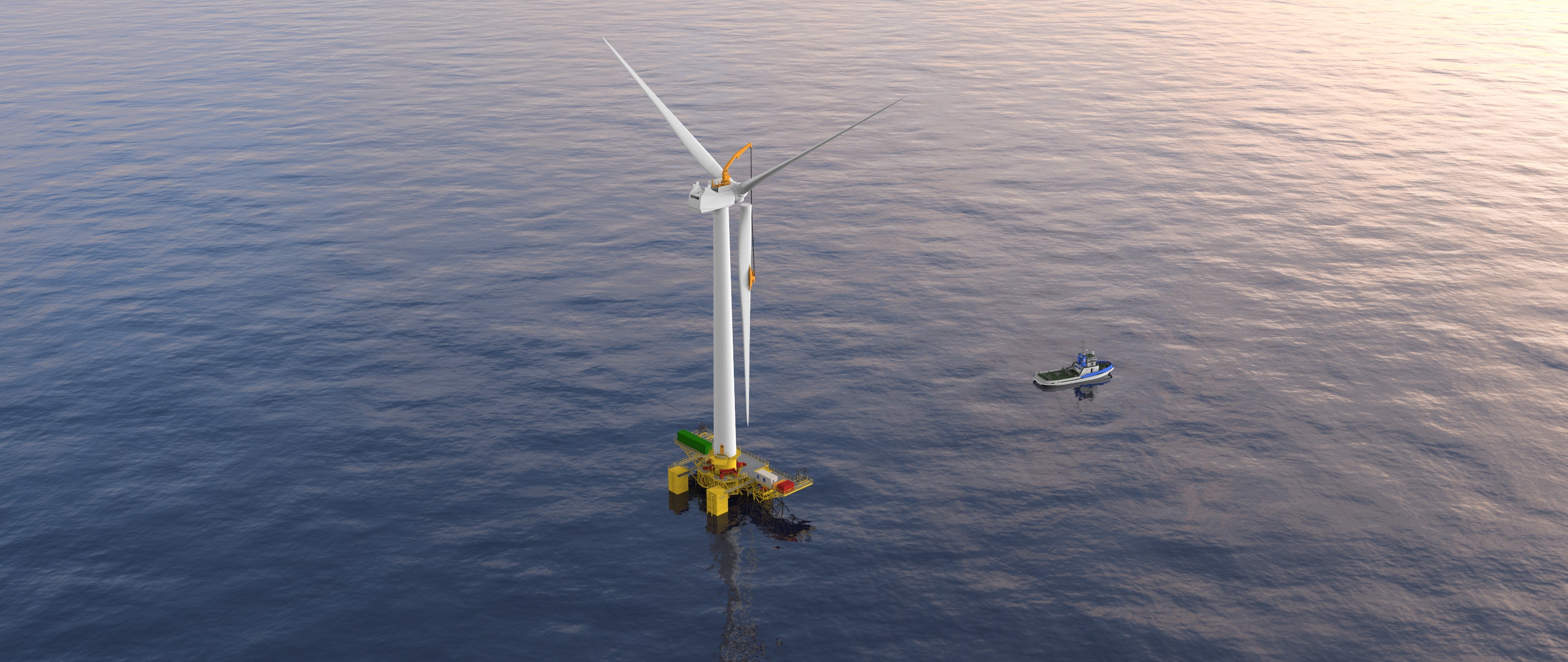

While jack-up vessels need to reach down to the seabed for a fixed point to prevent movements of the crane, ATOMS will be transported by a conventional small tugboat to the wind turbine and will be conveniently coupled to it with the coupling ring structure.

The system can be used for both bottom-fixed and floating wind turbines.

For bottom-fixed wind turbines, this solution prevents the movement of the service crane. In the case of floating wind turbines, ATOMS will allow the crane and turbine to move along as one single body, eliminating any relative movement. ATOMS system is able to couple with any steel or concrete tubular-tower-type foundation structure. It provides a robust large barge for equipment transport and handling. ATOMS project will achieve a reduction of around 50% of CO2 emissions, while cutting the overall maintenance costs by up to 25% and the overall Levelized Cost of Energy by 5-7%.

The project has led to a more ambitious platform design, evolving from a barge to a semisubmersible unit. Esteyco chose a more suitable, but costlier, design for better future commercialisation. While this is positive for achieving a more effective solution, it has resulted in increased manufacturing work and a delayed start.

ATOMS prototype has been installed in the Canary Islands and tested on ELISA/ELICAN experimental offshore wind tower developed as a result of two EU H2020 co-funded projects of the same company, Esteyco.

Once tested, the system will be certified, qualified and patented. Further funding will be needed for the first pre-serial platform (around EUR 3 to 5 million).

You can find more info on its design on the project page.

- Reference

- EMFF-BEW-2019-958976

- Project duration

- 1 Sep 2020 - 31 Oct 2024

- Project locations

- Spain

- Overall budget

- €3 545 110

- EU contribution

- €2 481 58070% of the overall budget

- Project website

- ATOMS