Waste heat is a common challenge in industries requiring high temperatures. With the help of heat exchangers, waste heat can be recovered and channelled to other processes within the same facility. But corrosive exhaust gases and high temperatures pose critical challenges to engineers when they try to extract thermal energy from flue gases.

In 2017, ten companies and institutes from across Europe joined forces within the ETEKINA project to develop and test a new type of heat-pipe-heat-exchanger (HPHE) for energy-intensive industries. Heat can be transferred efficiently to a cold part of the pipe.

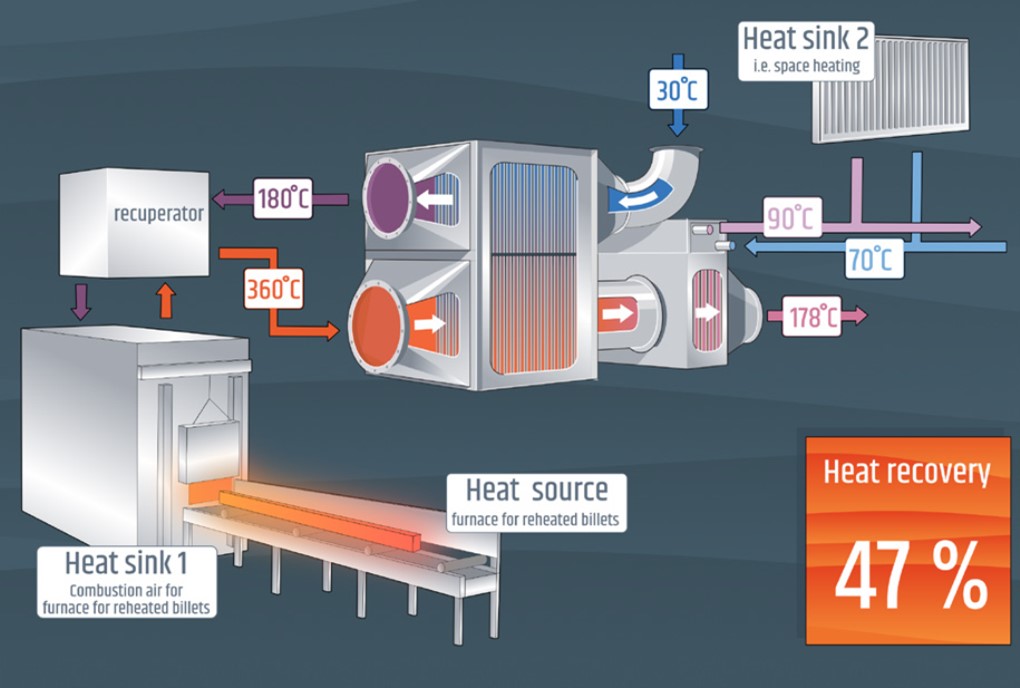

In the ETEKINA project, engineers arranged many such heat pipes and created a heat exchanger design according to the specific needs of each of the production plants involved in the project: three factories producing aluminium, steel, and ceramics, respectively.

The hot production steam passes at the bottom of a container to heat the liquid inside the many tubes working together in parallel. At the other end of the heat exchanger, cool air, water or thermal oil flows along, absorbing the heat of the condenser sections. This heated air or water can now be transported to parts of the production line where it can be re-used to preheat combustion air, treat automotive parts, or dry clay for example.

The heat pipe heat exchanger concept developed during this project is highly scalable and can be adapted to any type of industrial exhaust in a wide range of temperatures for different heat sinks (hot air, hot water, pressurised water, thermal oil etc.).

In 2021 three individually designed HPHEs were installed in the three factories and the system has been monitored until the end of the project. More than 40% of the waste heat stream is being recovered in all three factories. The energy recovered in the three industrial settings is now used to reduce the industrial plants’ energy consumption, thus reducing their greenhouse gas emissions in accordance with new regulations.

Lowering waste energy was not the only objective of the project. Equally important was the commercial viability of the technology and a technology readiness level TRL7 has been achieved. Calculations show that the Return of Investment (RoI) of the ETEKINA prototypes are also extremely interesting for a commercial exploitation.

MORE INFORMATION

CORDIS project factsheet

Twitter account

LinkedIN account

- Reference

- H2020-EU.3.3.1. - Reducing energy consumption and carbon footprint by smart and sustainable use

- Project duration

- 10 Jan 2017 - 10 Mar 2022

- Project locations

- SloveniaSpainItaly

- Overall budget

- €5 539 610

- EU contribution

- €4 617 68083.4% of the overall budget

- Project website

- https://www.etekina.eu/

Stakeholders

Coordinators

IKERLAN S. COOP

- Address

- Pº. J. M.ª Arizmendiarrieta, 2, 20500 Arrasate-Mondragón Guipúzcoa, Spain

- Website

- https://www.ikerlan.es/