AggregaCO2

The AGGREGACO2 project aims to establish the first commercial production plant in the EU for carbon-negative aggregate, offering a technically robust and sustainable alternative to conventional aggregates. The process integrates CO₂ captured from refinery operations into Accelerated Carbonation Technology (ACT), enabling the revalorisation of Air Pollution Control Residues (APCr) — currently classified as hazardous waste and landfilled. The plant will achieve an annual production capacity of 56,000 tonnes of carbon-negative aggregate, revalorise 22,000 tonnes of APCr per year, and utilise 2,200 tonnes of captured CO₂.

In partnership with PETRONOR (part of the Repsol Group) and O.C.O, the project will demonstrate the integration of ACT processes within traditional oil and gas refining sites, supporting their transition towards more sustainable, circular manufacturing models.

CarBatteryReFactory

The 24,000 square meter FENECON site in Iggensbach, Bavaria, with modern production halls and warehouses, development laboratories and offices, went into operation at the beginning of 2024. The production processes were successfully ramped up to series production. Used electric vehicle batteries from German premium vehicle manufacturers are reused in the industrial storage systems. “Zero life" and "second life" EV batteries can be used equally. FENECON's storage platforms make full use of the many advantages of these batteries - such as high product quality, long service life, particularly high efficiency, easy transportability and liquid-based temperature management.

GIGA-SCALES

The GIGA-SCALES project will establish a pioneering industrial-scale ZIRFON membrane production plant, with a yearly production capacity equivalent to 20 gigawatt (GW) of alkaline water electrolyzers. This project includes the latest generation of ZIRFON membranes which boost stack efficiency and hence reduce renewable electricity to produce green hydrogen production. With the planned entry into operation already set for October 2025, the project will avoid an estimated 6.13 million tonnes of CO₂ equivalent greenhouse gases over the first ten years of operation. Co-funded by the EU Commission, GIGA-SCALES allows hydrogen to take a pivotal role in a cleaner and greener world.

Helexio® line

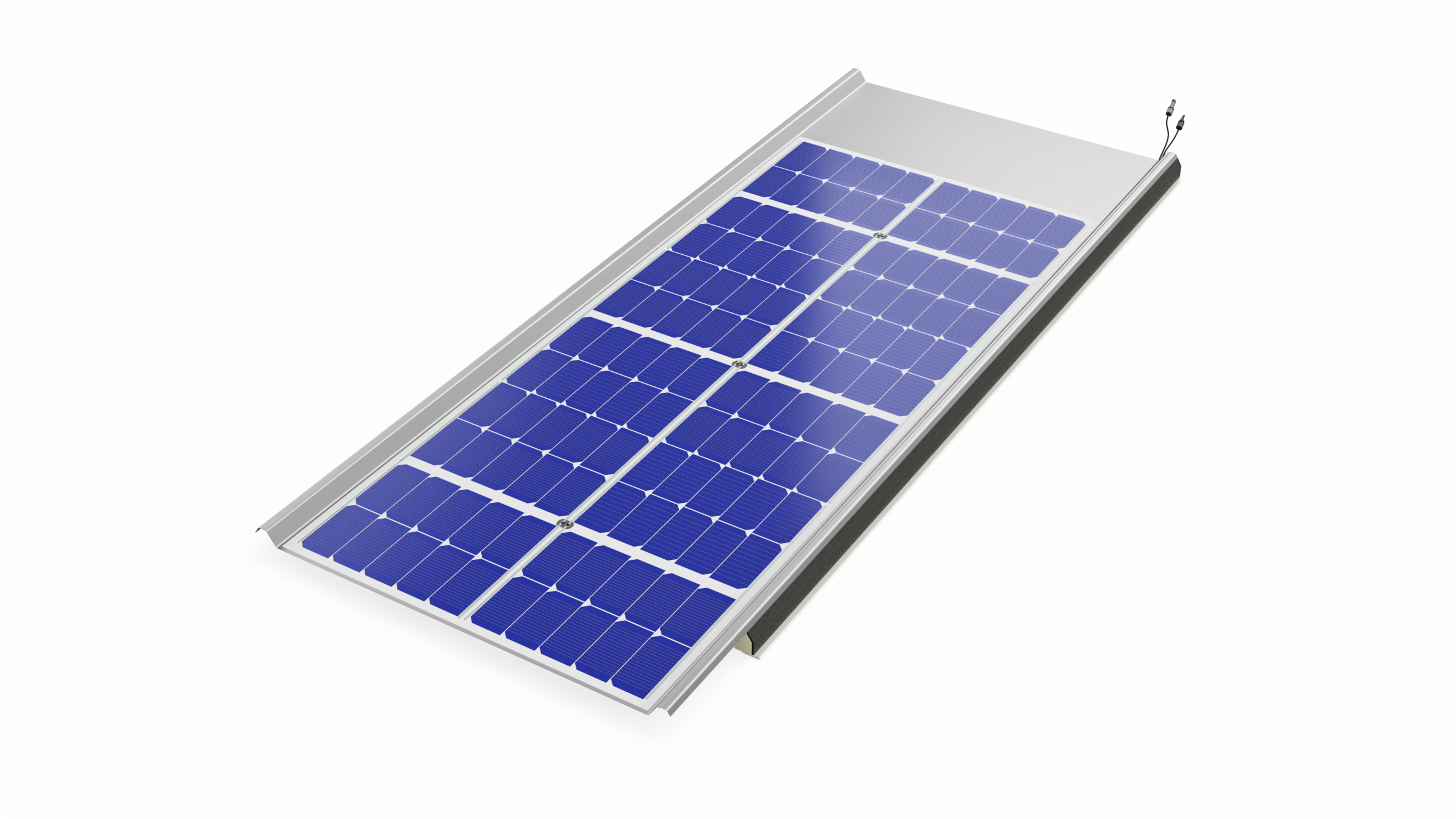

The Helexio® line is the first full-scale manufacturing plant dedicated to producing Helioroof® located at Contrisson (France), an innovative Building Integrated PhotoVoltaic (BIPV) steel roofing solution. Combining high-efficiency solar technology with advanced insulation, Helioroof® offers a lightweight, flexible, and easy-to-install alternative to conventional roofing and solar panels. Designed for all roof types, it is ideal for both new constructions and the renovation market, providing an efficient way to upgrade buildings with sustainable energy solutions. With the Helexio® Line plant soon fully operational, this breakthrough technology is ready to reduce greenhouse gas emissions, driving the transition to energy-independent buildings across Europe.

InnoSolveGreen

The InnoSolveGreen project pioneers an innovative Energy-as-a-Service solution, enabling industrial consumers to meet 100% of their annual electricity demand with cost-effective, locally generated solar photovoltaic plus storage (PV-plus-storage) systems. The project features two PV-plus-storage installations: one on-site at an industrial facility and another off-site utility-scale system. Successfully implemented at the Carlsberg brewery in Lithuania, InnoSolveGreen has played a key role in the site’s decarbonisation, ensuring 100% renewable energy supply and reducing greenhouse gas emissions. Over its first decade, the project aims for complete GHG emission avoidance, setting a benchmark for sustainable industrial energy solutions.

SHEEFT

SHEEFT Project aims to contribute to the large-scale deployment of clean energy production systems throughout Europe, thanks to its innovative Stykon® photovoltaic panel, light, durable, and designed for easy installation on existing large buildings rooftops (commercial, industrial, logistic and public) with low-bearing capacities.

SHEEFT project will allow the reduction of GHG emissions by over 360,000 tons of CO2 equivalent over the first 10 years of operation, and will lead to the creation of 100 direct and 150 indirect jobs.

TopSOEC

TopSOEC is a 500 MW Solid Oxide Electrolysis Cell (SOEC) stack module manufacturing facility in Denmark, operational in early 2025. This facility will manufacture advanced electrolyser components used in the production of renewable fuels and chemicals. SOEC stacks are highly efficient, offering 20-30% electricity savings compared to alternative technologies, thereby lowering the levelized cost of hydrogen production. The facility will help to significantly decarbonize hard-to-abate sectors, such as steel and fertilizer production, supporting the EU's climate neutrality goal by 2050. It is expected to reduce greenhouse gas emissions by approximately 7.6 million tonnes of CO2 over the first ten years of operation.

W4W

The Waga 4 World (W4W) project at Can Mata, Spain, converts landfill gas into grid-compliant biomethane using WAGABOX® technology. Developed by Waga Energy, the unit produces 70 GWh of renewable natural gas (RNG) per year, supplying 14,000 households or 200 buses, while avoiding 13,000 tonnes of CO₂ emissions annually. The biomethane is injected into the gas grid via a 6 km pipeline. Co-financed by Waga Energy, a bank loan, and the EU Innovation Fund (€2.4M grant), the project supports the EU Green Deal and demonstrates a scalable circular economy solution for waste-to-energy conversion.